Interested In

Microelectronics packaging and interconnects reliability

Thermal management of Microelectronics System

Semiconductor device manufacturing

Mechanical Testing of Materials

Finite Element Analysis (FEA)

Materials characterization

Projects

- Specimen fabrication & test setup of thermo-mechanical fatigue testing of Micro-bumps in Microelectronics

The study is conducted to experimentally observe the intermetallics (IMCs) effect on the micro-bumps reliability in thermal cyclic loading. A unique test specimen is designed and going to be fabricated. Manufacturing parameters such as reflow time & temperature effect on bump morphology are targeted to be monitored during specimen fabrication.

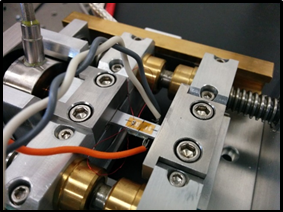

- In situ Single Lap Shear Test of Micro Scale Solder Joints

Single lap shear test will be conducted in a 20-30µm thick solder joint to capture the shear behavior of solder joint with different amount of intermetallic thickness. Lap shear specimen is designed and will be fabricated. Fabrication parameters will be controlled to achieve desired surface morphology in solder joint. A Micro tensile stage will be used to conduct the test to observe the effect of IMCs on the mechanical behavior of micro solder bonds.

- Thermo-mechanical fatigue reliability test simulation for micro-bumps in Microelectronics packaging

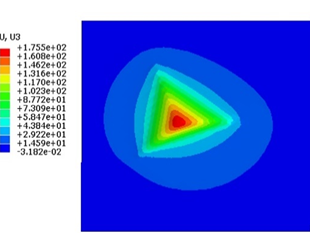

The project aims to observe the effect of intermetallics (IMCs) presence on the fatigue life cycles in microelectronic packages. Commercial finite element analysis software ANSYS APDL programming is used to simulate the effect of the IMCs’ presence in the micro solder bump with 30µm standoff height.

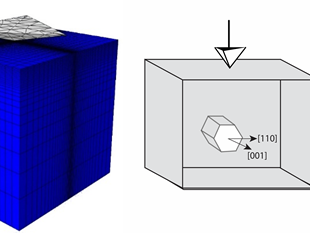

- Single Crystal Plasticity Finite Element Analysis (CPFE) of Cu6Sn5 Intermetallic

Plasticity of a material is defined by the slip system parameters which are unavailable for Cu6Sn5 in literature. A comparative method based on nanoindentation test and crystal plasticity finite element analysis was used to predict the critical resolved shear stress, initial hardening modulus and saturation stress of Cu6Sn5 that can imitate the plastic behavior of single crystal Cu6Sn5. Abaqus software with user material (UMAT) support has been utilized.

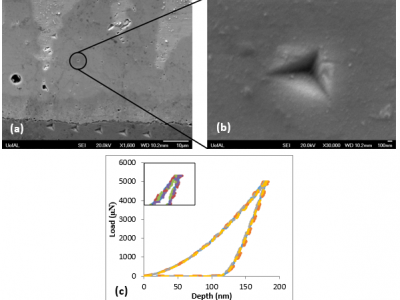

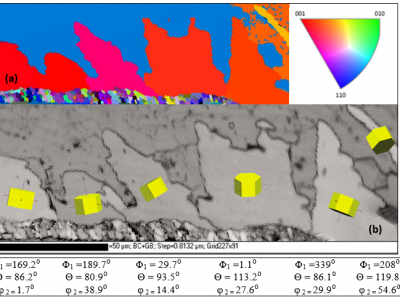

- Elastic-plastic Properties determination of Cu6Sn5 Intermetallic using Nanoindentation & Electron Backscatter diffraction (EBSD) analysis

This study was conducted to fully characterize Cu6Sn5 IMC using nanoindentation. Elastic properties (Young’s modulus & Hardness) was extracted directly from nanoindentation and a reverse analysis model proposed by Dao was used to predict the plastic properties (Yield strength, strain hardening exponent) of the IMC. EBSD analysis was used to observe the preferred grain growth orientation of Cu6Sn5.